ELECTRICAL CABINET EQUIPMENT MAINTENANCE

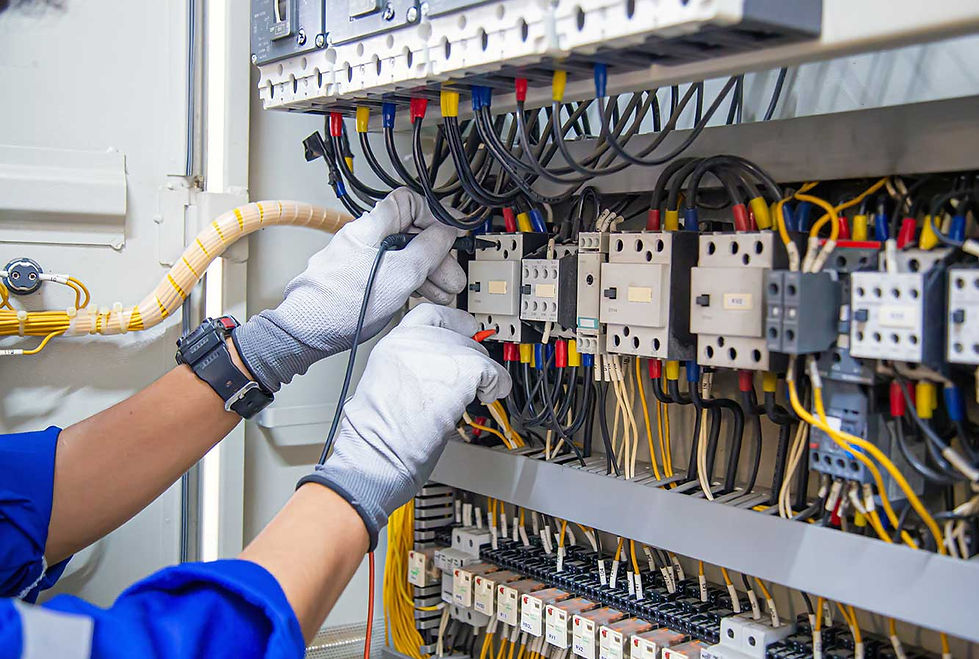

Maintenance of electrical cabinets of wastewater treatment systems is an important part of operating automatic treatment technology. When performing proper maintenance of electrical cabinets of wastewater treatment systems, businesses can reduce the risk of short circuits, prevent electrical overloads, ensure stable PLC-SCADA signals and maintain 24/7 operation. Many units in Ho Chi Minh City, Hanoi, and Da Nang ask the questions: "How often do you need to maintain electrical cabinets of wastewater treatment systems?", "How much does it cost to maintain electrical cabinets of wastewater treatment systems?" and "What are the signs of a faulty electrical cabinet of wastewater treatment systems?". The answer depends on the frequency of operation, the chemical environment and the quality of the equipment.

When the wastewater treatment system electrical cabinet is not maintained periodically, components such as contactors, protective relays, frequency converters (VFDs), IO modules, pH sensors, and water level sensors may lose accuracy, leading to pump stoppage, air blower stoppage, causing the microbiological system to become unstable, violating QCVN and causing odors. Maintenance of wastewater treatment cabinets also supports insulation assessment with Megger, checking wire contact, removing terminal oxidation, replacing silica gel desiccant packets, and cleaning conductive dust.

✅ Benefits of maintaining electrical cabinets of wastewater treatment systems

Maintenance of the wastewater treatment system's electrical cabinet provides:

-

Stabilizes voltage and load current to the inverter.

-

Optimizes the life of contactors, MCBs, MCCBs.

-

Reduces the risk of fire and explosion in humid environments.

-

Protects the PLC from random IO errors.

-

Maintains accurate water treatment sensor data.

-

Prevents downtime that causes environmental testing penalties.

✅ Wastewater treatment electrical cabinet maintenance process

During the maintenance of the electrical cabinet of the wastewater treatment system, the technician will:

-

Check MCCB, MCB, ELCB, anti-shock.

-

Tighten the cos head and busbar to avoid ignition.

-

Clean the cooling fan, ventilation slot.

-

Check the error and warning log of the inverter.

-

Backup the PLC, SCADA, HMI program.

-

Check the overload relay and timer.

-

Measure the insulation resistance of the power transmission line.

-

Check the online sensor power supply.

-

Evaluate the contactor vibration after the impact.

-

In addition, the maintenance of the electrical cabinet of the wastewater treatment system should be combined with a grounding check <2–4 Ohm, ensuring lightning protection.

✅ Signs that you need to urgently maintain the electrical cabinet of the wastewater treatment system

-

The circuit breaker trips continuously.

-

The smell of burning plastic or melting plastic at the end of the cos.

-

The VFD screen reports an overcurrent/overload error.

-

The water level sensor signal is lost, causing the tank to overflow.

-

The air blower starts slowly and vibrates a lot.

-

The cabinet temperature increases abnormally.

If these symptoms occur, the business must immediately maintain the electrical cabinet of the wastewater treatment system to avoid spreading.

✅ Standard maintenance cycle

-

Monthly: clean the cabinet, tighten the terminal.

-

Quarterly: check the contactor, cooling fan.

-

6 months: measure the insulation of all power lines.

-

12 months: general inspection and replacement of worn components.

In coastal areas or areas with chlorine vapor, the frequency of maintenance of the electrical cabinet of the wastewater treatment system should be increased.

✅ Cost of maintenance of electrical cabinets of wastewater treatment system

Cost depends on:

-

Number of inverters and PLCs to be inspected.

-

Level of corrosion caused by corrosive chemicals.

-

Requirement to backup and archive operating logs.

-

Level of terminal/wire degradation.

Reputable units will provide detailed quotes by item.

✅ Current trends in electrical cabinet maintenance

Factories are applying:

-

IoT real-time overload warning.

-

AI predicts contactor failure.

-

SCADA automatically logs errors.

-

Wireless temperature sensors monitor busbars.

Thanks to this, maintenance of wastewater treatment system electrical cabinets becomes smarter and more cost-effective.

✅ Current trends in electrical cabinet maintenance

Factories are applying:

-

IoT real-time overload warning.

-

AI predicts contactor failure.

-

SCADA automatically logs errors.

-

Wireless temperature sensors monitor busbars.

Thanks to this, maintenance of wastewater treatment system electrical cabinets becomes smarter and more cost-effective.

✅ Recommendations for management

To optimize the maintenance efficiency of the electrical cabinet of the wastewater treatment system:

-

Create an internal SOP checklist.

-

Attach a maintenance history sticker to the cabinet.

-

Save images to prove quality.

-

Control spare parts periodically.

✅ Conclusion

Performing maintenance of the wastewater treatment system's electrical cabinet according to the correct procedure will increase the equipment's lifespan, reduce downtime, ensure output meets QCVN standards, avoid fines, stabilize production and increase the efficiency of the entire system. This is an important item that every wastewater operation unit needs to prioritize.

CÔNG TY TNHH CAMIX

34 - 36, Đường 57A, P.Tân Tạo, Q.Bình Tân, Tp.HCM

Tel: (028) 3601 5966 - Fax: (028) 5407 3938 - Email: info@camix.com.vn

Hotline: 0903.318.778 (Ms.Phuong Linh) - 0976.164.441 (Mr.Anh Khoa)